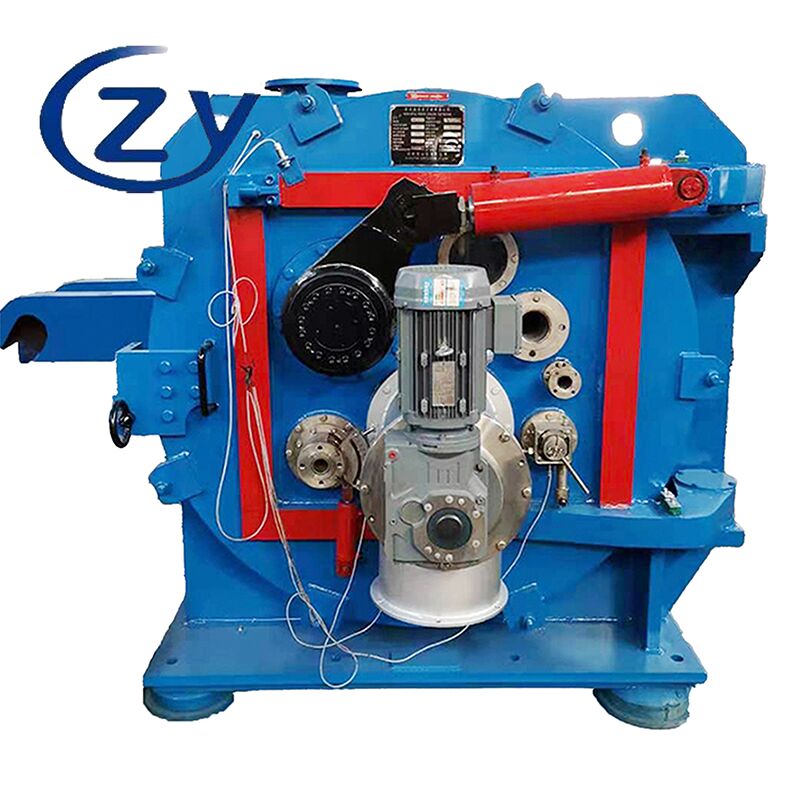

Industrial Scraper Discharge Centrifuge for High-Efficiency Starch Slurry Solid-Liquid Separation

Λεπτομέρειες:

| Τόπος καταγωγής: | Χενάν Κίνα |

| Μάρκα: | ZY |

| Αριθμό μοντέλου: | GK1250 |

Πληρωμής & Αποστολής Όροι:

| Ποσότητα παραγγελίας min: | 1 ΣΕΤ |

|---|---|

| Τιμή: | 50000 |

| Συσκευασία λεπτομέρειες: | ΞΥΛΙΝΟ ΚΟΥΤΙ |

| Χρόνος παράδοσης: | 2 μηνών |

| Όροι πληρωμής: | L/C,T/T |

| Δυνατότητα προσφοράς: | 5 σετ ενός μήνα |

|

Λεπτομερής ενημέρωση |

|||

| Μέγεθος: | Προσαρμοσμένο ανάλογα με τον τύπο | Πρώτες ύλες επεξεργασίας αμύλου: | Κασάβα, πατάτα, γλυκοπατάτα |

|---|---|---|---|

| Αξιοπιστία: | Ανώτερος | Όνομα προϊόντος: | Φυγόκεντρος ξύστρας |

| Εφαρμοστέες Βιομηχανίες: | Εργοστάσιο Τροφίμων & Ποτών | Εξουσία: | Μηχανοκίνητο |

| Ένταση κραδασμών: | Οριακός | Ικανότητα: | Ανώτατο όριο |

| Λειτουργία μηχανήματος: | Εξοπλισμός αφυδάτωσης αμύλου | Θερμοκρασία: | Χαμηλός |

| Συντήρηση: | εύκολος | Ποιότητα: | Κορυφαίας ποιότητας |

| Αντοχή: | Διαρκής | Τεχνικές Επεξεργασίας: | ραμμένα |

Περιγραφή προϊόντων

Industrial Scraper Discharge Centrifuge for High-Efficiency Starch Slurry Solid-Liquid Separation

Product Description:

Structure and performance characteristics:

- High-speed operation achieves fast, efficient separation of starch and fibrous by-products.

- Precision structural design ensures stable, reliable performance and elevates solid-liquid separation efficiency.

- Durable anti-wear components extend equipment life and substantially lower long-term maintenance expenses.

- Engineered for large-scale industrial workflows, this equipment is fully suited for 24/7 uninterrupted continuous operation.

Technical Parameters:

| Parameter | Value |

|---|---|

| Noise Level | Low |

| Power | Electric |

| Size | Customized As Per The Type |

| Reliability | High |

| Maintenance | Easy |

| Temperature | Low |

| Material | Stainless Steel |

| Vibration Level | Low |

| Capacity | High |

| Application | Separation Of Solids From Liquids |

| Automatic Dewatering Machine | Yes |

| Starch Peeler Centrifuge | Yes |

Performance Features:

- Completely automated operation simplifies daily processes and decreases labor needs for starch lines.

- Integrated hydraulic system dynamically adjusts actuators in real time to sustain stable operation under different loads.

- PLC control system delivers precise, consistent component movements with intuitive parameter adjustment.

- Variable-frequency drive/hydraulic coupling provides smooth, shockless startup and shutdown.

Customization:

- Brand Name: ZY

- Model Number: GK

- Place of Origin: Henan, China

- Temperature: Low

- Vibration Level: Low

- Noise Level: Low

- Application: Separation Of Solids From Liquids

- Durability: High

- Special Features: Automatic Dewatering Machine, Peeler Centrifuge

![]()

FAQ:

- Q: What is Decanter Scraper Centrifuge?

- A: The Decanter Scraper Centrifuge is a kind of centrifugal separator produced by ZY with model number GK, which is from Henan, China.

- Q: What are the features of Decanter Scraper Centrifuge?

- A: The Decanter Scraper Centrifuge has high separation efficiency, low energy consumption, and strong production capacity.

- Q: Are the materials of Decanter Scraper Centrifuge safe?

- A: Yes. The Decanter Scraper Centrifuge is made of high-quality stainless steel, which is safe and durable.

- Q: What is the application of Decanter Scraper Centrifuge?

- A: The Decanter Scraper Centrifuge is widely used in the separation and clarification of materials in the chemical, pharmaceutical, food, and other industries.

- Q: What is the warranty period for Decanter Scraper Centrifuge?

- A: The warranty period is one year from the date of shipment.

Θέλετε να μάθετε περισσότερες λεπτομέρειες σχετικά με αυτό το προϊόν